The Robot Army Enters The Construction Site! The GHZ25-12 Welding Workstation Starts The Intelligent Manufacturing Of Steel Cages

Jun 18, 2025|

Jun 18, 2025| Reshaping the benchmark for infrastructure efficiency

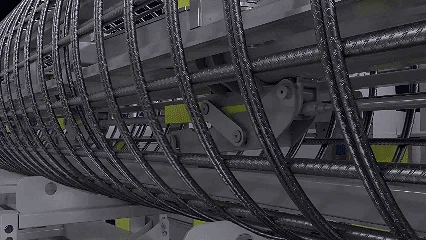

The fully automatic steel cage welding workstation GHZ25-12 developed by GUTE Machinery has ended the traditional manual welding mode with disruptive technology, injecting new impetus of intelligent manufacturing into infrastructure fields such as subways, bridges, and highways.

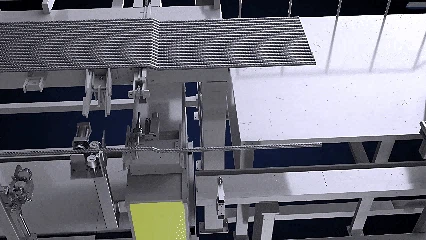

1. Extremely fast and efficient, with a leap in production capacity

- 35 seconds/bar: The welding cycle of a single main bar is shortened to within 35 seconds, which is 300% more efficient than manual work;

- 20 minutes to form: The welding of a 9-12 meter steel cage skeleton takes only 20 minutes, and the winding and welding of the bars are completed in 25 minutes:

- 7x24 continuous operation: The durable design of the equipment supports all-weather operation and seamlessly matches the rhythm of engineering breakthroughs.

2. Unmanned whole process, consistent precision

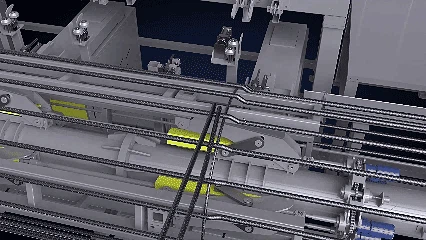

- Four-dimensional automation system: main reinforcement feeding → detection and positioning → winding reinforcement welding → finished product delivery, zero human intervention in the whole process;

- Intelligent error correction mechanism: automatic detection of main reinforcement length error and alarm and material throwing, eliminating human errors;

- Zero defects in welding points: real-time monitoring of welding quality, no hidden dangers of false welding, supervision and acceptance upgraded from "daily squatting" to data verification'

3. Smart hub, one-click switching

- 50 sets of parameters are pre-stored: suitable for complex specifications such as 1500-2500mm pile diameter, φ18-32mm main reinforcement, etc., and can be called up with one click on the touch screen;

- Dual-mode welding: supports single/double main reinforcement, single/double winding reinforcement, plum blossom welding/full welding and other processes, and can be switched freely;

- Three-layer permission isolation: engineer parameter configuration, administrator maintenance, and worker operation interface are independent to prevent accidental touch and ensure safety.

4. Hard-core performance, all-round adaptability

- Heavy-duty design: 6 tons load-bearing, compatible with 8-14mm winding and variable pitch requirements;

- Modular layout: 30mx11m area can be disassembled and reassembled, suitable for factory and construction site scenes;

- IP21S protection: mechanical moving parts + welding safety dual protection to ensure the safety of human-machine collaboration.

The equipment has pushed the production of steel cages from "labor-intensive" to "intelligent assembly line", reducing labor costs by 50% and shortening construction time by 40%.

Contact us

...............................................................................

Tel: +8613281163201

WhatsApp: +8613281163201

Email:sales6@cdgute.com

..............................................................................

https://www.gutemachinery.com

Send Inquiry